Ebor Mills was first established more than two centuries ago. Now, as it undergoes a complete reinvention and we prepare to welcome a new community of residents, we’re looking back at the evolution of Ebor Mills.

The original Ebor Mill was built in 1819 by Hiram Craven, a contractor and stone mason based in Keighley. It had seven bays and three storeys and was powered by water from Bridgehouse Beck – a huge internal water wheel once occupied the eastern end of the building, with the mill race in front. The original mill building still stands as the spinning mill (1) – the roadside building just off Ebor Lane – and, like the rest of the remaining mill structures, it is Grade II listed.

At first the spinning mill was rented out, but by 1834 the firm Cravens & Sugden had been set up by Hiram Craven in partnership with his two sons, and the Cravens were operating the mill themselves. Between 1847 and 1848 the spinning mill was extended and several cottages (2) were built for mill workers.

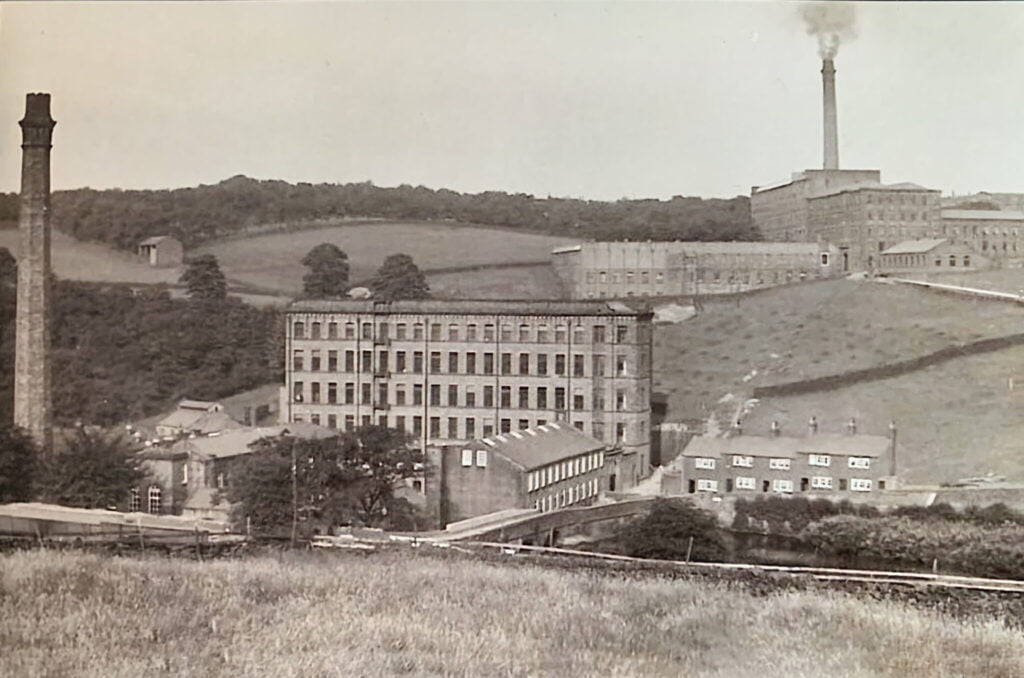

In 1851 Cravens & Sugden was dissolved and the Ebor Mill complex was sold to the Merrall brothers. Hartley Merrall first established a weaving business in the area in the early 19th century, and his four sons carried on the family business with great success. Documents suggest the Merralls had already been renting Ebor prior to buying it, and in 1844 they had built Lees Mill (3), which was conveniently located immediately to the east of Ebor. The two mill complexes were soon sharing facilities and running in tandem.

With the business-savvy Merralls at the helm, Ebor entered a period of rapid expansion and upgrades. An additional steam-powered mill and engine house was built, likely in the 1860s, but this was soon replaced by the warehouse (4) and weaving sheds (5). In 1885 neighbouring Lees Mill was devastated by fire, but by 1892 it had been completely rebuilt, and the Merralls also took the opportunity to improve Ebor during this period. The original spinning mill was extended between 1886-7 and the economiser (6), boiler house (7) and chimney (8) were also constructed, as was a new, much larger, multi-storey spinning mill (9).

This large complex of buildings would have been a hive of industry, and the worsted, a fine quality wool yarn, produced there was in high demand. It was said that Merralls workers formed one of the most prosperous communities in Yorkshire, and by 1910 the company was said to have 15,000 spindles and 1,400 looms, making it one of the county’s largest worsted spinning operations (10).

Watch this space for Part Two of the evolution of Ebor Mills‘, which will take us up to the present day. In the meantime, find out more about the new community we’re creating in the heart of Haworth – discover our homes here.

(1) We’re creating several unique homes within the former spinning mill.

(2) Five of the mill workers’ cottages survive and we are renovating three of them.

(3) Lees Mill was demolished after a fire in the 1960s.

(4) We’re creating several apartments and townhouses within the former warehouse.

(5) We’ve paid homage to the saw tooth, ‘North Light’, roofs of the weaving sheds in the design of some of our new build homes, which will stand where they once did.

(6) We’re creating a standalone home within the former economiser.

(7) We’ll retain and restore part of the old boiler house as a historical asset.

(8) The original chimney is still very much a feature of Ebor Mills’ roofline.

(9) The multi-storey spinning mill built in the late 1880s was sadly destroyed by fire in 2010.

(10) Incidentally, the Merralls also owned Lowertown Shed (also known as Lower Holme Mill) at Oxenhope, which was redeveloped by Skipton Properties 15 years ago.